Comparing mode shapes from different meshes

In ANSYS 12.0.1, the RSTMAC command has been introduced to allow a user to compare mode shapes between two different meshes.

Background:

When performing rotordynamic analyses, one may use the PLCAMP or PRCAMP command to plot/list a Campbell diagram. This allows users to see how the modes change with rotational speed. To accomplish this, ANSYS internally uses the modal assurance criterion (MAC) to determine which modes are the ‘same’ between different rotational speeds.

This functionality has been exposed in 12.0.1 to allow users to compare any set of modes via the RSTMAC command. Please keep in mind that the original usage was based on the same mesh. Consequently, the RSTMAC command works best on the same mesh, although if one uses a fine enough mesh, nodes from one mesh can be matched to the other mesh.

Usage:

- Perform modal analysis of one model

- Perform modal analysis of another model, saving results to a different jobname or directory

- Enter the General Postprocessor /POST1 and enter the RSTMAC command, specifying the result files for both models. Additional control over the load step and substep(s) of interest can be input

A listing of possible matching modes will then be printed in the Output Window/File for the user to examine.

Note that a nodal component may be specified — in the first model, created a nodal component (or Named Selection in Workbench Mechanical application) of a specific region you may wish to use for comparison, rather than have ANSYS try to compare the entire mesh. This is useful, for example, if you may have ribs/stiffeners that move positions between the two meshes and wish to exclude them from the MAC calculations.

Example:

The RSTMAC output from a simple example is copied below:

****** Modal Assurance Criterion (MAC) VALUES ******

Solutions are real

Rows: 20 substeps in load step 1 from file case1\file.rst

Columns: 20 substeps in load step 1 from file case2\file.rst

1 2 3 4 5 6 7 8 9 10 11 12

1 0.993 0.001 0.001 0.003 0.000 0.000 0.063 0.000 0.001 0.004 0.021 0.007

2 0.017 0.991 0.000 0.001 0.005 0.000 0.012 0.000 0.006 0.000 0.000 0.001

3 0.005 0.001 0.979 0.013 0.009 0.002 0.008 0.000 0.001 0.000 0.002 0.002

4 0.002 0.007 0.004 0.592 0.370 0.040 0.015 0.003 0.015 0.000 0.001 0.001

5 0.003 0.001 0.000 0.085 0.165 0.662 0.079 0.010 0.000 0.015 0.000 0.000

6 0.003 0.002 0.003 0.242 0.081 0.237 0.336 0.204 0.017 0.024 0.019 0.009

7 0.059 0.021 0.019 0.008 0.240 0.098 0.549 0.004 0.268 0.011 0.009 0.018

8 0.009 0.002 0.007 0.274 0.242 0.289 0.084 0.164 0.042 0.000 0.001 0.007

9 0.000 0.000 0.004 0.029 0.007 0.094 0.130 0.859 0.002 0.006 0.000 0.048

10 0.000 0.008 0.002 0.022 0.061 0.012 0.248 0.019 0.852 0.003 0.000 0.000

11 0.013 0.000 0.002 0.000 0.008 0.006 0.003 0.016 0.021 0.833 0.117 0.022

12 0.016 0.000 0.001 0.002 0.003 0.000 0.002 0.012 0.016 0.117 0.860 0.247

13 0.005 0.000 0.002 0.000 0.000 0.000 0.027 0.004 0.006 0.118 0.501 0.872

14 0.004 0.000 0.000 0.005 0.000 0.001 0.008 0.001 0.030 0.000 0.008 0.428

15 0.000 0.000 0.000 0.000 0.000 0.001 0.072 0.007 0.006 0.002 0.007 0.018

16 0.005 0.003 0.005 0.017 0.000 0.000 0.005 0.010 0.007 0.100 0.001 0.318

17 0.007 0.001 0.001 0.000 0.010 0.001 0.003 0.000 0.000 0.000 0.000 0.000

18 0.002 0.000 0.000 0.000 0.002 0.000 0.008 0.004 0.000 0.021 0.000 0.024

19 0.000 0.004 0.003 0.000 0.003 0.000 0.004 0.015 0.017 0.009 0.001 0.022

20 0.000 0.000 0.000 0.000 0.001 0.000 0.007 0.003 0.008 0.002 0.000 0.001

<...truncated ouput...>

*** NOTE ***

Solutions matching in RSTMAC command succeeded.

8 pairs of solutions have a Modal Assurance Criterion (MAC) value

greater than the smallest acceptable value (.9).

********************************** MATCHED SOLUTIONS **********************************

Substep in Substep in MAC value Frequency Frequency

case1\file.rst case2\file.rst difference (Hz) error (%)

1 1 0.993 0.37E+02 4.4

2 2 0.991 0.11E+02 0.9

3 3 0.979 0.94E+02 2.4

14 13 0.919 0.28E+03 1.2

15 14 0.987 0.55E+02 0.2

17 15 0.976 0.30E+02 0.1

18 16 0.970 0.31E+03 1.1

19 17 0.958 -0.23E+03 0.7

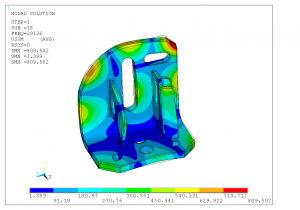

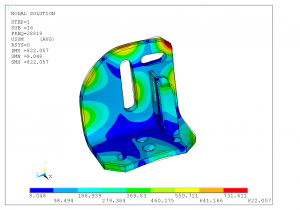

As can be seen from above, a ‘matrix table’ of the modes is printed in ASCII form, along with modes that match, based on the MAC value specified (default is 0.9). For this example, mode #18 from the first model and mode #16 from the second model are thought to match. These are displayed below, and one can see that the modes are indeed similar despite the first model including an extra part (i.e.,geometries and meshes are different between the two cases):

Using RSTMAC allows users to compare different designs by checking to see how much modes change frequencies and whether modes may ‘flip’ order or if modes may be added/removed by design changes.

Hello,

this is interesting info on ulterior use of the RSTMAC.

Frank

Hello ANSYS-Users,

is there a way to *get the matching mode numbers for automtic postprozessing?

thanks for help